What We’ll Unpack in This Article (TL;DR)

Inventory management software is powerful for reducing excess, avoiding stockouts, and ensuring smooth workflows in your warehouses. But not all inventory management software features matter equally. To cure common inventory problems, look for specific features which actually move the needle, such as:

- AI-powered demand forecasting.

- Supplier insights and score cards.

- Clear executive dashboards.

- Inventory segmentation.

- Forecast accuracy and benchmarking.

This article gives you clear guidance of features that matter when it comes to improving service, capital, and customer satisfaction.

When companies evaluate inventory management software, they’re often shown long lists of capabilities. But not all inventory management software features matter equally. Some might look impressive on paper or in a demo, but have little impact on inventory performance. To avoid common inventory problems like excess and stockouts, you need to know which features really drive better forecasting, investments, and decision-making.

Whether you’re adopting inventory software for the first time or you’re looking to upgrade your solution, here’s a breakdown of inventory management software features that move the needle when it comes to improving service, capital, and customer satisfaction.

What Should Inventory Management Software Help You Do?

There’s a common misconception with inventory management software: it should mainly help you track inventory. But the best use of this demand planning tool is to help you make better decisions before inventory becomes a problem.

The most effective inventory management software features help you do four critical things:

- Prevent problems (not react to them): Too many systems focus on only flagging excess or stockouts after they already exist. The best inventory planning software works upstream – using demand forecasts, lead times, and service targets to prevent excess and shortages.

- Balance service levels & inventory investment: Inventory management software should help you intentionally decide where to invest in service and where to accept risk, based on SKU importance, demand behavior, and financial impact.

- Support smarter forecasting: Inventory decisions are rooted in forecast accuracy. Software should continuously improve forecasts, measure error, and translate that insight into smarter ordering decisions.

- Give leaders confidence in numbers: Executives don’t need more reports – they need clarity. The right inventory management software features clearly answer questions like:

- How much inventory do we really need to order, and when?

- Where is cash tied up unnecessarily?

- What happens if demand or lead times change?

Ultimately, the systems that deliver the most value are the ones that help organizations control inventory before it shows up on the balance sheet

Top Inventory Management Software Features That Move the Needle

In practice, only specific inventory management software features consistently deliver measurable improvements in service levels, inventory turns, and working capital.

They include:

1. AI-powered demand forecasting

Demand forecasting is the core of inventory performance. When forecasts are inaccurate, everything downstream suffers – excessive inventory grows, safety stock balloons, and stockouts lead to disappointed customers. But AI-driven forecasting uses sophisticated technology to improve forecast accuracy. Research from McKinsey shows AI can reduce inventory levels by up to 30% by improving demand forecasting.

AI demand forecasts use advanced models to predict demand, taking into account seasonality, trends, and variability. They also have notable features other models don’t, like no demand and zero-demand forecasting (which identifies SKUs with no forecasted or historical usage) and unusual sales detection (to prevent outliers from throwing off your forecast).

2. Supplier insights

Suppliers play a sneaky role in supply chain performance. If lead times slip or orders arrive short, you’ll feel it in your delivery times and bottom line. And nearly 40% of companies struggle to track their shipments when they’re in-transit. That’s why supplier insights are a critical inventory management software feature.

Your inventory management solution should track supplier performance, and clearly show you insights at-a-glance, such as lead times and on-time percentage. Strong vendor scorecards are useful – they can help you shift from reacting to supplier performance to proactively managing it.

3. Clear executive dashboards

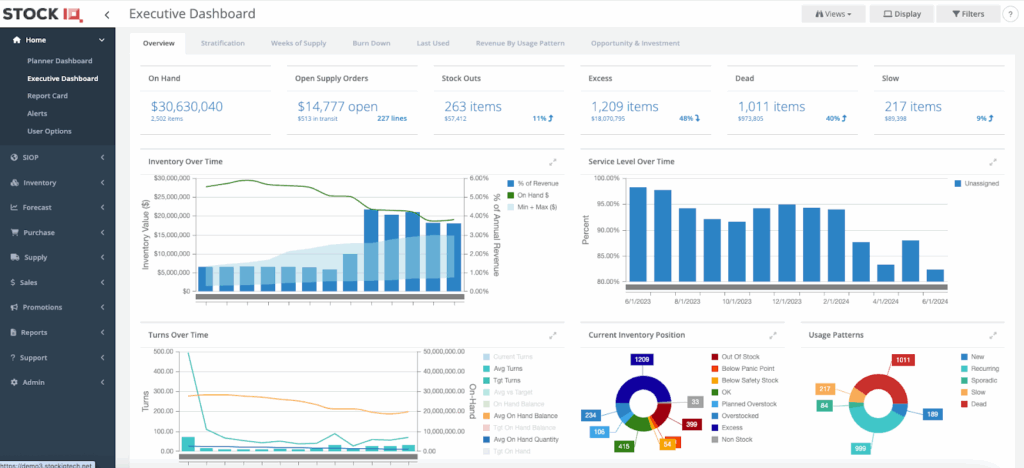

Executive dashboards are where inventory planning connects to business performance. For leadership teams, these dashboards should answer core questions, and should incorporate all relevant data. For example, StockIQ’s Executive Dashboard was built for advanced financial health checks and C-suite visibility, and it combines ERP facts with StockIQ metrics/calculations. It also shows metrics CFOs care about, such as on-hand inventory value, projected inventory, turns, cost of goods sold, carrying costs, and EOQ, to support financial decision-making.

4. Inventory segmentation

Not every product deserves the same service level, safety stock, or replenishment strategy – and inventory management software should make those differences clear. Effective inventory segmentation features break SKUs into meaningful groups based on value, velocity, and predictability, allowing teams to apply the right policies to the right items. For example:

- ABC segmentation classifies items by business impact, often based on sales velocity, revenue contribution, or margin. “A” items typically drive the majority of revenue or service risk, while “C” items may sell infrequently or contribute less financially.

- XYZ segmentation focuses on demand behavior and forecastability. Some SKUs are stable and predictable, while others are highly volatile or sporadic.

5. Forecast accuracy & benchmarking

Forecasts are never 100% accurate – it’s the nature of the process. But the top inventory management software both measures forecast accuracy and benchmarks it against a simple, transparent baseline (like a naive six-month rolling average). By measuring forecast accuracy, you can improve it, and therefore improve your ordering policies.

Inventory management software can be powerful for improving your service level and margins. But software alone won’t improve your operations – you need to be using the right features. With capabilities like AI-powered forecasting, inventory segmentation, executive dashboards, and supplier insights, you can transform inventory management from a chaotic, reactive process to one that is predictable and strategic.

StockIQ: Inventory Management Software Features You Need

In the modern supply chain, inventory challenges are here to stay. But with the right inventory tools, you can drive tangible improvements that translate into cash, time and service impact.

That’s where StockIQ makes a difference. StockIQ is advanced, user-friendly supply chain management software that allows you to control inventory, simplify ordering, and improve forecasting. We use powerful, AI-driven demand forecasts to give you the inventory clarity and visibility your business deserves.

Find out how StockIQ can give you access to the inventory management software features you need by contacting us today or requesting a StockIQ demo.

Frequently Asked Questions About Inventory Management Software Features

1. What is inventory management software?

Inventory management software helps organizations plan, control, and optimize inventory levels so the right products are available at the right time, without tying up unnecessary cash in excess.

2. What should inventory management software help you do?

Regardless of the specific features, inventory management software should help you do a few specific things:

- Prevent problems ahead of time, instead of reacting to them.

- Balance service levels and inventory investment.

- Support smarter forecasting.

- Give leaders confidence and clarity when it comes to numbers.

3. Which inventory management software features matter most?

A few specific inventory management software features consistently deliver measurable improvements. These include:

- AI-powered demand forecasting.

- Supplier insights and score cards.

- Clear executive dashboards.

- Inventory segmentation.

- Forecast accuracy and benchmarking.