What We’ll Unpack in This Article (TL;DR)

Managing a complex supply chain requires decision-makers to collaborate internally, navigate external suppliers, and operate in notoriously unpredictable conditions. In today’s market, legacy planning tools and ERP solutions simply can’t keep up. That’s why market leaders are turning to comprehensive supply chain planning software: platforms designed specifically to anticipate demand, align cross-functional teams, and optimize inventory.

To evaluate different supply chain planning tools, you should:

- Look for key capabilities, such as advanced forecasting, AI-driven insights, supplier management features, and inventory optimization.

- Make sure it can handle long, variable lead times.

- Choose a system that allows you to address the root cause of inventory issues.

In this guide, we’ll break down how to evaluate supply chain planning software for increasingly complex demand networks.

Managing a complex supply chain network is a heavy lift: it requires decision-makers to collaborate internally, navigate external suppliers, and operate in notoriously unpredictable conditions. And in today’s market, traditional planning tools and ERP solutions simply can’t keep up, because they weren’t built for the depth of forecasting, supplier variability, or inventory that the modern supply chain requires. That’s why market leaders are turning to comprehensive supply chain planning software: platforms designed specifically to anticipate demand, align cross-functional teams, and optimize inventory before it ever hits the warehouse.

When you leverage the right supply chain planning solution, you add a vital layer of visibility, data, and organization to your inventory processes. Armed with these tools, you can best meet customer demand, keep operations running smoothly, and deliver an exceptional customer experience. But choosing your solution can be tricky, due to the number and diversity of tools available.

In this guide, we’ll break down what today’s supply chain planning software solutions really need to handle, and how to evaluate them for increasingly complex demand networks.

How is Supply Chain Planning Changing?

Supply chain planning software needs to meet the needs of the modern supply chain, which is changing at a breakneck pace. It’s something that we consider to be “a cross-functional contact sport,” which involves R&D, sales/marketing, finance, and supply chain.

What exactly is supply chain planning? It’s the process of forecasting demand, aligning supply to meet that demand, and determining the optimal inventory, purchasing, and operational strategies to keep products flowing efficiently through the business

There are three core supply chain planning capabilities that dictate how your business functions, and which your software solution should. They are:

- Demand Planning & Forecasting

Demand planning & forecasting are processes that refer to proactively planning your inventory investments, revenue, cash flow, and financial results, which allow your business to keep enough stock flowing to meet demand, while minimizing waste.

- Supplier Management

Supplier management uses key processes (such as forecasting & planning, metrics, and business reviews) to strategically navigate these relationships.

- Inventory Management

Inventory management dictates how inventory and supply are managed and tracked in your business, and includes ABC stratification, XYZ analysis, service levels, and order policies. It’s not only the physical movement of inventory, but also covers your inventory strategy around your processes.

Over the past several years (and even months), the pace of change has accelerated. Longer global lead times, shifting global tariff policies, and increasingly unpredictable demand patterns have made it clear that yesterday’s planning processes don’t work in today’s environment.

Here are some of the major trends shaping the demand planning landscape:

- Demand volatility has become the norm, including frequent spikes, dips, and unpredictable buying behavior.

- Tariffs have become a central, persistent issue. A McKinsey survey of 100 companies found that 82% of respondents said their supply chains are affected by new trade tariffs. Meanwhile, 39% said they’re seeing increases in supplier and material costs, and 30% reported reductions in customer demand.

- Artificial intelligence is a mainstream tool with growing applications. It’s essential for identifying events, filtering noise, and improving forecast accuracy. Notably, it’s also necessary for boosting resilience: experts from the World Economic Forum predict that “AI will protect global supply chains from the next major shock.”

- Lead times are longer. Many companies face 90–150+ day lead times, driving a need for deeper, more forward-looking planning.

- Financial visibility is now a core requirement. CFOs want insight into working capital impact, inventory ROI, and service-level trade-offs.

It’s clear that supply chain planning has evolved from spreadsheets and ERP-based forecasting into a dynamic, data-driven, financially aligned discipline. To thrive in this ecosystem, organizations need sophisticated supply chain planning software that can guide faster, smarter decisions.

What Capabilities Should Today’s Supply Chain Planning Software Include?

Modern supply chain planning software must do far more than track inventory or generate a forecast. Today’s vast networks require tools that anticipate uncertainty, guide cross-functional decisions, and reduce unnecessary costs.

The most effective solutions share several core capabilities:

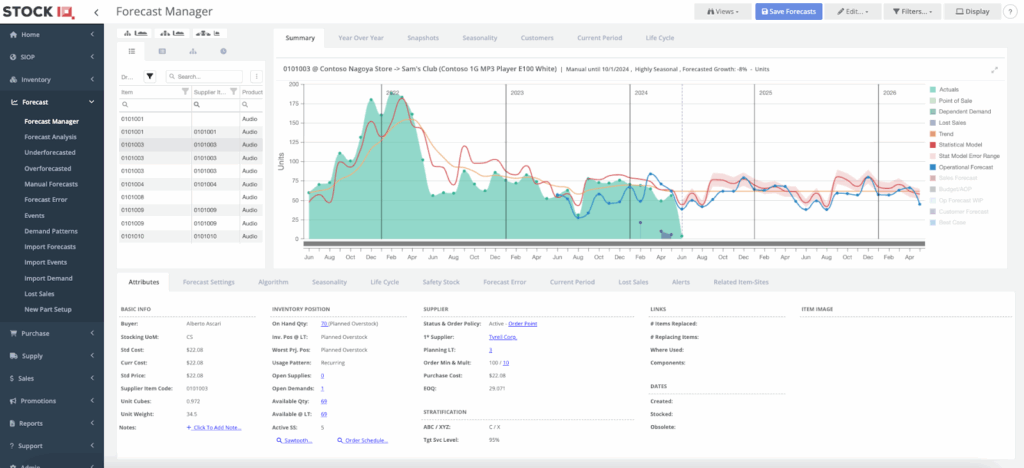

1. Advanced forecasting & AI-driven insights

A strong supply chain planning tool has to have deep, sophisticated demand forecasting abilities, rooted in AI. Key capabilities should include:

- Statistical forecasting with seasonality and trend detection.

- AI-based event identification that isolates unusual spikes, promotions, and market disruptions.

- Succinct dashboards, which tell you key inventory takeaways at-a-glance.

These capabilities help planners adapt quickly to volatile demand while aligning assumptions across the business.

2. Supplier management

With long, variable, and increasingly fragile supply lines, supply chain planning software must bring a layer of visibility and data to supplier relations. For example, your tool should provide you with supplier scorecards, which clearly show lead times, on-time delivery performance, and other key metrics. This level of real-time data allows you to proactively manage your suppliers, instead of reacting to problems after they occur.

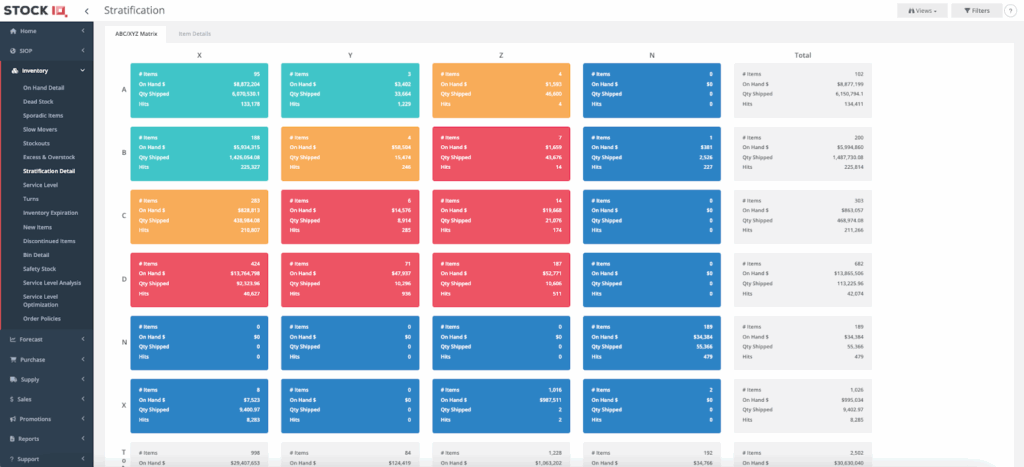

3. Inventory optimization & policy automation

Inventory is where forecasting and supply decisions become financial outcomes. To best inform these outcomes, modern platforms should include:

- ABC/XYZ segmentation, updated frequently to reflect changing SKU behavior.

- Automated safety stock calculations using forecast error, service level, and lead-time uncertainty.

- Dynamic order policies (order point, min/max, lot-for-lot, sporadic demand strategies) tailored at the item-location level.

4. Integrated S&OP & cross-functional coordination

The platform you select must help your team break out of silos and align around a single, trusted plan. Think: unified demand, supply, and financial planning views, enabling your people to easily work from the same data, assumptions, and priorities.

5. Usability, automation, & decision support

Your tools should empower your team to make better, faster decisions. Instead of clunky, slow, or overly-complicated software, look for a solution that has user-friendly features, such as:

- Clear dashboards & role-specific views.

- Automation of routine tasks, like purchase order generation and alerting.

- Fast analytics that enable daily, weekly, and monthly planning horizons.

Features like these help organizations maximize their margins, smooth workflows, and maybe most critically, shift from firefighting to proactive supply chain planning.

Tips for Choosing the Perfect Supply Chain Planning Software

With so many tools claiming to “optimize” your supply chain, it can be tough to weed through the options.

Here’s how to choose a system built for today’s complex demand networks:

- Prioritize forecast accuracy: Many tools produce forecasts, but only a few improve them meaningfully. Look for software that offers statistical forecasting + AI-driven event detection, and that takes external factors into account.

- Make sure it can handle long, variable lead times: If your lead times span months, you need software that can look far ahead and model uncertainty. With that in mind, choose a system that offers lead time tracking, supplier performance analytics, and that offers lead time support through metrics like burn rate.

- Evaluate its inventory optimization depth: Don’t just stop at calculating min/max rate. Look for features that will ensure you hold the right amount of inventory at the right time, such as ABC/XYZ segmentation, safety stock calculations, and automated order policy recommendations.

- Choose a system that helps prevent problems in the first place: To really create value, your chosen solution should stop inventory problems at the source, not just call out symptoms. Look for platforms that holistically improve your inventory rates, reduce safety stock levels, and enhance demand forecasting accuracy.

- Ensure the software fits your team: The best solution is one that your team adopts, and that smoothly integrates into your existing. Be sure the tool you choose has role-based dashboards, intuitive workflows, clear recommendations, and configuration without IT dependency.

StockIQ: Your Comprehensive Supply Chain Planning Software

Your business deserves powerful, accurate supply chain planning software. If you’re looking to improve your supply chain planning processes and leverage real-time data for your decision-making, StockIQ is here to help.

StockIQ is advanced, user-friendly supply chain management software that combines supplier management, demand forecasting, and inventory optimization together in one intelligent planning platform.

If you’re ready for supply chain planning software that improves the way you run your business, contact us today or request a StockIQ demo.

Frequently Asked Questions ABout Supply Chain Planning Software

1. How is supply chain planning changing?

There are several major trends shaping the supply chain today, including demand volatility, tariffs, artificial intelligence, long lead times, and the need for financial visibility. This has created an ecosystem where spreadsheets and ERP systems are not enough. Instead, leading organizations need sophisticated supply chain planning software that can guide faster, smarter decisions.

2. What capabilities should supply chain planning software include?

The most effective solutions share several core capabilities:

- Advanced forecasting & AI-driven insights.

- Supplier management features (such as scorecards).

- Inventory optimization & policy automation (like ABC stratification).

- Integrated S&OP & cross-functional coordination.

- Usability, automation, & decision support.

- How can you choose the perfect supply chain planning software?

Start by prioritizing forecast accuracy: many tools produce forecasts, but only a few improve them meaningfully. Next, make sure your solution is suitable for SKUs with long lead times, and that it has in-depth inventory optimization features. Also, look for a solution that gets to the root cause of issues, and that integrates with your current solution and workflows.