What We’ll Unpack in This Article (TL;DR)

If you want to improve margins and maximize your business’ performance, you need to take a good look at your suppliers – late shipments, quality misses, and unexpected cost spikes can have ripple effects. However, strong supplier performance management benefits include:

- Lower operational and rework costs.

- Reduced safety stock requirements.

- Fewer stockouts and lost sales.

- More accurate planning and ordering.

Here’s how disciplined supplier performance management drives tangible returns, and why it’s becoming a core focus for resilient, cost-effective supply chains.

Improving margins in inventory-based businesses requires more than smart ordering decisions – every component of your supply chain plays a role in profitability and customer satisfaction. That’s why supplier performance management is now a priority concern: every late shipment, quality miss, or unexpected cost spike can cascade into higher costs and disappointed customers.

Supplier performance management benefits are numerous. By tracking and improving supplier fundamentals – quality, cost stability, and on-time delivery – organizations achieve significant ROI through lower inventory investment, fewer disruptions, and better service levels.

Here’s how disciplined supplier performance management drives tangible returns, and why it’s becoming a core focus for resilient, cost-effective supply chains.

What is Supplier Performance Management (& Why Does It Matter for ROI?)

In order to unlock supplier performance management benefits, we have to start with the fundamentals. Supplier performance management (SPM) is the structured process of monitoring, measuring, and improving how suppliers deliver against expectations. At its core, supplier performance management helps organizations answer a simple but essential question: are our suppliers helping or hurting our ability to meet demand profitably?

In practice, SPM brings discipline to areas that often go unmanaged: tracking lead-time accuracy, benchmarking on-time delivery, and identifying where supplier behavior is driving excess inventory or stockouts.

Unreliable suppliers create ripple effects throughout the entire supply chain, forcing teams to over-buy or raise safety stock levels, which can quickly erode margins – industry studies show inventory distortion costs retailers $1.7 trillion annually.

That’s where ROI comes into focus. When suppliers perform better, organizations can:

- Decrease safety stock levels, because lead times become more predictable.

- Reduce excess carrying costs and rush orders.

- Improve service levels through fewer stockouts and missed customer commitments.

Ultimately, SPM matters because it protects two things every inventory-based business depends on: customer loyalty and cash flow.

How Does Supplier Performance Improvement Generate ROI?

Supplier performance is one of the most overlooked — yet highest-leverage — drivers of supply chain ROI. When suppliers consistently deliver products on time, with stable lead times and fair costs, your entire operation becomes more predictable and profitable. Conversely, every missed delivery, cost surprise, or quality issue triggers a litany of unplanned expenses: expediting fees, inflated safety stock, and customer service issues.

Supplier performance improvement generates ROI in several measurable ways:

- Lower costs. By identifying under-performing suppliers, you reduce defective goods, expedited shipping, warranty claims, rework, and other failure costs.

- Reduced safety stock requirements, as lead times and quality become more predictable.

- Risk mitigation. Supplier Performance Management provides visibility into delivery delays, quality issues, supplier capacity constraints or compliance problems – so you avoid or reduce the cost of supply chain disruptions.

- Fewer stockouts and lost sales thanks to reliable inbound supply. One analysis of hundreds of products found that avoiding stockouts can lead to a 5% revenue bump.

- More accurate planning and ordering, due to stable inputs and fewer disruptions.

- Better supplier relationships & innovation. High-performing suppliers can partner more closely, enabling innovation, better lead-times or tailored service – these feed value but are often harder to quantify directly.

- Quality & brand protection. Poor supplier performance (quality defects, delayed shipments) causes hidden costs (returns, lost sales, reputation damage). Supplier performance management helps reduce those. For example, real-time monitoring helps reduce recalls.

It’s not just anecdotal claims: researchers have found that when businesses take a collaborative and strategic approach to supplier relationships, they can achieve greater operational efficiency, drive product development, and navigate market uncertainties.

Best Practices for Boosting Supplier Performance Management

Achieving notable supplier performance management benefits requires leaders to take a structured, ongoing approach to their suppliers. The goal? To improve visibility, strengthen resilience, and support more confident inventory planning.

With that in mind, here are the most effective best practices you can use for boosting supplier performance management in your business:

1. Measure what matters – constantly and transparently

Supplier performance can’t improve if it isn’t measured. First, focus on the metrics that have the greatest impact on cost and service:

- On-time delivery and lead time variability.

- Quality and completeness of orders.

- Cost accuracy and landed-cost stability.

- Responsiveness and communication.

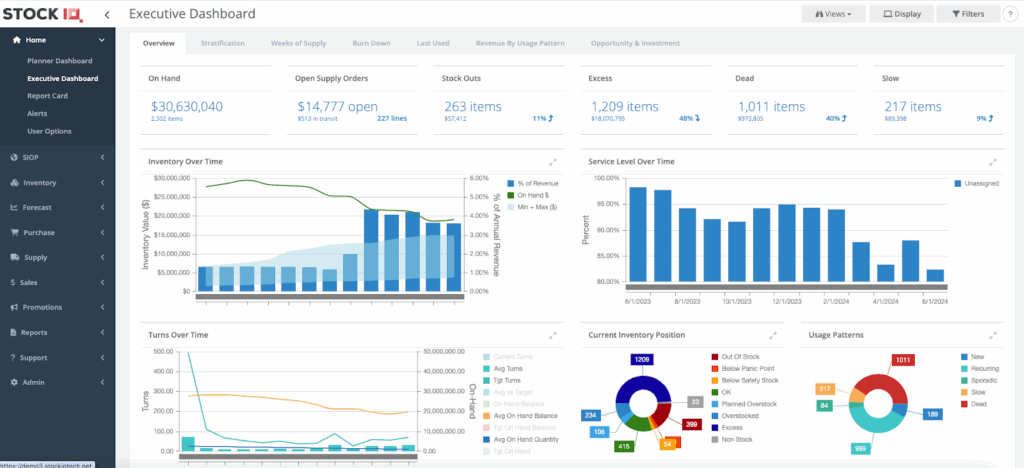

You can measure these metrics on your own by taking baselines and periodically checking in. Alternatively, if you’re using a comprehensive inventory management solution like StockIQ, you’ll have access to a supplier scorecard, which gives your team a clear picture of performance trends and opportunities for improvement at-a-glance.

2. Hold structured, proactive supplier reviews

Too often, the only time teams engage with suppliers is when something goes wrong. Instead, shift to proactive business reviews that share performance metrics and expectations, highlight upcoming demand and forecast changes, and surface risk early. These meetings can also allow you to strengthen alignment on service expectations and cost drivers.

Pro tip: go into these meetings armed with data. You can discuss a supplier’s on-time rate, lead times, and how their behaviors contribute to your margins (using concrete metrics from your inventory software, like cost of goods sold).

3. Use advanced supply chain tech to spot problems before they happen

Manual tracking makes it nearly impossible to catch performance slips early. However, supply chain planning software helps teams automatically identify changes in:

- Lead time trends.

- Cost fluctuations.

- Supplier reliability by SKU.

This allows you to address the root cause of supply chain issues, instead of needing to constantly firefight.

4. Align all business units around the same supplier metrics

A supplier’s true performance isn’t just whether the invoice matches the PO – it’s how their reliability impacts service levels, cash flow, and inventory investment. With SPM, you can break down business unit silos by aligning procurement, finance, and operations around the same source-of-truth supplier insights. For example, you can share key insights with finance executives, such as safety stock requirements and carrying cost changes, to help inform critical financial decisions.

Boosting supplier performance can reduce volatility, improve your business’ efficiency, and strengthen your financials. When teams measure supplier performance consistently, collaborate proactively, and leverage the right technology, supplier performance becomes a powerful source of ROI rather than a recurring source of disruption.

Maximize Your Supplier Performance ROI with StockIQ

Supplier performance is a financial engine that can help take your business to new heights. When suppliers deliver reliably, cost-effectively, and on time, organizations can plan with confidence, carry less inventory, and hit higher service levels without inflating costs. But capturing that value requires visibility, accountability, and structure.

That’s exactly where StockIQ excels.

StockIQ is advanced, user-friendly supply chain management software that combines supplier management, demand forecasting, and inventory optimization together in one intelligent planning platform. With tools like supplier scorecards, lead-time trend analysis, and real-time variability detection, teams can shift from reacting to supplier issues to preventing them.

If you’re ready to turn supplier performance into a true competitive advantage, contact us today or request a StockIQ demo.

Frequently Asked Questions About Supplier Performance Management

1. What is Supplier Performance Management (SPM)?

Supplier Performance Management is the structured process of evaluating and improving how suppliers deliver against expectations for on-time delivery, cost accuracy, quality, and lead-time reliability. These metrics directly influence inventory levels, service performance, and overall supply chain costs.

2. Why does SPM matter for inventory planning?

Supplier performance plays a huge role in day-to-day inventory operations. For example, it’s one of the biggest drivers of safety stock levels and replenishment accuracy. When lead times or fill rates are unpredictable, organizations compensate with excess inventory, emergency buys, and inflated buffers.

3. What are the benefits of managing supplier performance?

Better supplier performance leads to:

- Lower safety stock requirements.

- Fewer stockouts and lost sales.

- Reduced expediting and emergency freight.

- Improved margin protection through stable costs.

- Less rework caused by incomplete or incorrect orders

These improvements flow directly into stronger working capital, higher turns, and improved profitability.